How to create airing cupboard shelving

TOOLS

MATERIALS

- Wood screws (4 X 30mm)

- 4 X self drill metal fixers

- 2 X double ball catches

- Mitre adhesive

- 5 X light dowel moulding (25 X 25 X 2400mm)

- 1 X whitewood PSE timber (18 X 144 X 1800mm)

- Whitewood PSE timber (44 X 44 X 1800mm) of an offcut spacer

SAFETY

- Primarily used to house hot water tanks and even combi boilers, airing cupboards are often an underutilised storage space. If you’re short on storage or without a utility room, an airing cupboard with fully flexible and custom shelving is ideal. Air duvets, store boxes and hang your linen, washing and towels to warm through, out of sight.

- Our step by step instructions have been designed as a guideline to make one large airing cupboard shelf. This bracket system is designed to hold wooden dowels that you can easily reconfigure if you need to hang a bulky duvet or support a heavy storage box.

- We used Whitewood PSE and light hardwood dowel for this build, but you can experiment with other structural materials and finishes for different looks.

Installing shelving in airing cupboard with a working boiler or tank

- If your airing cupboard still has a hot water tank or combi boiler in, it’s vital that your shelving doesn’t prevent access for servicing. Safe ventilation and good airflow between your hot water tank or boiler and storage area is also vital. You should allow for good clearance to ensure air circulation is efficient. We recommend seeking professional advice to ensure that your spaces meet UK regulations.

- Consider the tolerance, runout and alignment of your power saw blades when making cuts. Depending on the tolerance of your tools, you may find that dimensions are adjusted by approximately 3mm. We recommend marking the brackets after cutting them in half, to indicate which is slightly larger and will comfortably hold the dowel.

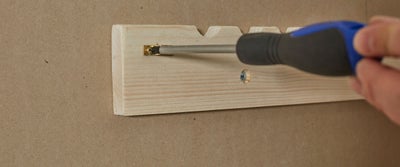

- As we worked on one long length of timber making multiple markings, we recommend using a pencil to mark through zones as a visual guide. Crosshatching an area that you shouldn’t work in, or circling drilling holes where lines intersect can be especially helpful.

- A chop saw or circular saw will ensure that your timber is cut accurately with precision speed. If you don’t have access to power tools, this project can also be completed with a universal saw. Ensure your timber is securely clamped, then slowly cut along your scored line with a clean and sharp saw blade.

- Always ensure that your construction area is well-lit and ventilated to prevent the inhalation of or irritation caused by dust and debris.